https://doi.org/10.3390/buildings12040459

Krishna Chauhan1, Antti Peltokorpi1, Rita Lavikka2 and Olli Seppänen1

1Division of Civil Engineering, Aalto College, 02150 Espoo, Finland

2VTT Technical Analysis Centre of Finland, 02044 Espoo, Finland

1. Introduction

2. Theoretical Background

3. Technique

4. Evaluation and Outcomes

5. Dialogue

6. Conclusions

Summary

Prefabrication is quickly growing in building, and former analysis has recognized numerous impacts of prefabrication on tasks. Modular product structure is a good enabler for prefabrication; nevertheless, practitioners would profit from extra express data on the impacts of prefabricated product sorts with completely different ranges of product modularity. This research investigates the connection between the modularity degree and the financial and non-monetary impacts of prefabricated merchandise. First, the literature on prefabrication and modularity is used to kind three propositions that are associated to product modularity and the advantages of prefabrication. The extent of modularity is taken into account with two dimensions: the proportion of modules and the module description element. Second, 4 prefabricated merchandise are analyzed to check the propositions. The evaluation revealed that (1) the extent of modularity adopted within the product is immediately proportional to the advantages. Extra particularly, (2) the next proportion of modules in a venture product contributes to larger cost-benefits. However, (3) prefabricated merchandise with extremely detailed module descriptions appear to result in larger non-monetary advantages, similar to higher ergonomics and work satisfaction. The research reveals new empirical proof on the connection between product modularity and the advantages of prefabricated merchandise. Value-benefit evaluation revealed that regardless that some prefabricated merchandise might have larger direct prices, the whole value can nonetheless be decrease than standard building when additionally contemplating the oblique advantages. Practitioners can make the most of the findings when choosing modular and prefabricated merchandise that finest fulfil their venture goals.

1. Introduction

A rise in prefabrication is a key driver for growing efficiency within the building sector [1,2] and plenty of research have mentioned the constructive impacts of prefabrication on decreasing waste (e.g. [3]), shortening schedules [4], bettering security [5], decreasing defects [6], and decreasing greenhouse fuel emissions [7]. Despite the fact that the implementation of prefabrication in a building venture impacts a number of components [7], empirical analysis has centered totally on a single product kind or a single influence issue. A number of impacts haven’t been completely evaluated and in contrast between completely different product classes.

Nearly all of earlier research have labeled prefabricated merchandise into 4 classes: (1) part manufacturing and sub-assembly, together with factory-made merchandise, similar to home windows, bricks, and tiles; (2) non-volumetric off-site building, together with merchandise that don’t create usable area, similar to structural frames and wall panels; (3) volumetric off-site building, together with pre-assembled items that create usable areas, similar to modular bogs, plant rooms, and bathe rooms; and (4) modular buildings, together with volumetric area items that additionally embrace the construction and exteriors, similar to faculties, motels, and jail blocks [8,9,10]. These classes, nevertheless, differ considerably of their scope, scale, and different fundamental traits, and selecting a prefabricated product amongst these for a venture is usually exclusionary. Thus, practitioners want appropriate decision-making frameworks to check prefabricated merchandise and comparative info on their general impacts.

Present analysis on the impacts of prefabricated merchandise argues {that a} larger degree of off-site building usually offers extra supply, value and high quality advantages to tasks however diminishes the pliability and innovativeness [8,9,10]; nevertheless, the extent of off-site building doesn’t totally take into account the product structure. We argue that the extent of product modularity must also be thought of when assessing completely different prefabrication merchandise and their suitability for a venture. Product modularity, the place the required features are assigned to particular bodily elements [11], usually allows the next degree of off-site building [10]. A number of the advantages of modularity, similar to a discount in CO2 emissions, discount in waste and minimizing the vitality losses might assist the development trade to contribute to the round financial system [12]; nevertheless, empirical analysis on assessing prefabricated product sorts along with their degree of modularity is scarce. As modularity is one important attribute of prefabricated merchandise, practitioners may gain advantage from extra exact data on the mixed impacts of the prefabricated product kind and the extent of product modularity on a building venture’s efficiency.

This paper goals to extend the data of prefabrication’s multifaceted impacts on building when modularity is taken into account a attribute of the prefabricated product. The research addresses the next analysis query: How do the prefabricated product kind and product modularity degree have an effect on the a number of dimensions of building efficiency? Concerning the efficiency measurement, each the constructive and destructive impacts, in addition to financial and non-monetary impacts, are thought of (see, e.g., [13]. Moreover, the extent of modularity is taken into account utilizing Hvam et al.’s [14] modularity framework.

The paper is structured as follows. First, the theoretical background introduces the literature on prefabricated product sorts and modularity evaluation frameworks. Then, as a synthesis of the literature, three propositions on the connections between the extent of prefabricated product modularity and venture impacts are derived. The strategy part describes the influence analysis methodology adopted on this research and the general design for empirical analysis to check the developed propositions. We chosen 4 prefabricated merchandise for the empirical evaluation, two representing volumetric merchandise and two non-volumetric merchandise with completely different modularity ranges. The evaluation and outcomes part focuses on revealing the patterns between the product traits and venture efficiency. The next part discusses the findings in mild of the earlier literature. The ultimate part summarizes the theoretical contributions and implications for apply and suggests avenues for additional analysis.

2. Theoretical Background

This part critiques the related literature on prefabricated product sorts and their impacts and product modularity. Based mostly on the literature evaluation, we then elaborate on our three propositions.

2.1. A number of Impacts of Prefabrication

Most earlier analysis on prefabrication has emphasised the significance of prefabrication and mentioned prefabrication as a direct resolution to enhance the development trade’s productiveness. Prefabrication can have an effect on the next venture components: value (e.g., [15]), time [4], waste [16], security [5] and defects [10].

The influence on value is probably the most controversial matter within the prefabrication literature, as prefabrication has been proven to be extra cost-efficient than on-site building resulting from decreased labor and materials prices and fewer building waste [17]. Boyd et al. [18] highlighted 30% financial savings from off-site building; nevertheless, prefabrication implementation additionally will increase capital prices [19] by way of investments in new equipment and factories (e.g., [20,21]). Prices are additionally elevated resulting from extra transportation prices [17], complicated strategies, and the requirement for extremely expert employees [22].

Concerning the components decreasing the whole prices, quite a few research have indicated {that a} shorter on-site building schedule is a significant attraction for implementing prefabrication [23,24,25]. In conventional building, main delays happen due to subcontractor work, disputes with stakeholders, delayed choice making between the shopper and advisor, sluggish info move between a number of subcontractors and venture staff members, poor web site administration and poor climate circumstances [26]. Most of those delay components could possibly be prevented with prefabrication. As an illustration, all of the prefabricated elements will be manufactured within the manufacturing facility, which might be impartial of the climate circumstances. Moreover, in contrast with standard building, prefabrication creates much less noise and waste, which lowers the possibility of a dispute with a building web site’s neighbourhood.

Waste discount is one main goal in implementing prefabrication, and it issues the several types of waste, similar to materials waste, defects, ready occasions and overproduction [3,27,28,29]. The most important traits of prefabrication for waste minimisation embrace having a factory-controlled course of, which is materials and resource-efficient by nature, the aptitude to assemble repetitive items in a managed setting and minimising waste due to much less climate intrusion and web site theft compared with standard building.

The security enhancements in prefabrication have been effectively introduced in earlier analysis. Fortunato et al. [30] defined the 4 causes of danger in conventional building: falls, overexertion/repetitive movement/working in a clumsy place, changing into caught in tools/objects/supplies, and being struck by an object/tools. Using prefabrication decreases these dangers due to the higher capacity to carry out complicated assemblies on the floor degree or off-site, the power to have fewer employees on-site, simpler monitoring of hazardous actions, much less involvement of the contractor and subcontractors and an general safer working setting [5,31]. The Development Trade Report [31] famous that 73% of prefabrication customers undertake security measures, together with security personnel appointments and the event and implementation of a well being and security plan. In distinction, solely 48% of non-prefabrication customers have adopted related measures.

Higher high quality in building is also achieved by implementing prefabrication [17,32,33]. Within the prefab manufacturing plant, high quality will be checked in a number of phases. For instance, the primary stage can be earlier than the prefabrication course of, the place the venture supervisor would conduct materials high quality checks to verify that each one the supplies meet particular high quality requirements. Second, high quality checks will be employed earlier than the unit’s set up, the place the venture staff might additionally ask for the approval of every unit and nonetheless then test the standard after the set up of the items. Thus, higher high quality will be achieved in a prefabrication course of than in a traditional one [6].

2.2. Prefabricated Merchandise and Their Impacts

Most earlier researchers have labeled prefabricated merchandise into 4 classes based mostly on the diploma of product standardization and off-site manufacturing [8,9,10]. Desk 1 presents these classes.

Desk 1. Prefabricated Product Classes.

| Class | Definition | Examples | Impacts | Sources |

| Modular buildings | Pre-assembled volumetric items that kind a whole constructing or a part of the constructing. Encompass the best degree of off-site manufacturing and standardization. | Motels, jail blocks, residential buildings, and homes. | Quickens the development schedule by as much as 50%, extra cost-efficient than panelized houses, and higher security and productiveness. | [10,34] |

| Volumetric pre-assembly | A selected a part of the constructing that encloses usable areas however doesn’t represent the entire constructing. | Modular bogs, plant rooms, and bathe rooms. | Discount in self-weight, much less complicated for upkeep, and general value discount. | [21,35] |

| Non-volumetric pre-assembly | Pre-assembled parts that don’t create usable areas. | Wall panels, structural frames, and bridge items. | Improves the structural efficiency, reduces ergonomic danger, and reduces value and time. | [36,37,38] |

| Element manufacture and sub-assembly | Sometimes, all the time made in a manufacturing facility and by no means thought of for on-site building. | Bricks, tiles, and home windows. | Impacts from conventional building. | [8] |

Within the present paper, our focus is on volumetric and non-volumetric pre-assembly.

Volumetric pre-assembly: Volumetric merchandise are manufactured for usable area and are then put in with or onto a constructing or construction. They embrace, for instance, prefabricated toilet items (PBUs), machine rooms, and hospital affected person rooms.

Non-volumetric pre-assembly: This class consists of the pre-assembly of non-volumetric gadgets, that’s, they can’t be used as usable areas. Examples embrace precast concrete parts, mechanical, electrical, and plumbing (MEP) hall parts, and water pipe modules. Most earlier research on prefabrication impacts have centered on non-volumetric merchandise. As an illustration, Hong et al. [15] utilized a precast balcony, precast staircase, and prefabricated air con panel to guage value impacts. Some research have evaluated particular non-volumetric product impacts, similar to cross-laminated timber (CLT) wall lateral conduct [36]; nevertheless, a number of impacts haven’t but been studied.

2.3. Product Modularity

Along with the extent of prefabrication, product modularity is one other facet to contemplate when analyzing industrialized merchandise and their impacts on building. Ulrich [11] talked about that an important character of a product’s structure is modularity which is expounded to performance, and a modular construction incorporates modules with standardized interfaces and interactions [39]. Modularization is the exercise by which module structuring takes place [40]. The identical product will be shaped with completely different modularization methods.

The generic advantages of modularity have been extensively mentioned within the literature. They embrace value financial savings, product selection, and the improved flexibility and simplification of complicated methods [12]). Wuni and Shen [41] argue that modular built-in building (MiC) transforms fragmented site-based constructing building into the manufacturing and meeting of value-added prefabricated modules; nevertheless, earlier research haven’t evaluated the advantages of prefabricated product sorts in building tasks when taking the extent of modularity under consideration. To fill this analysis hole, as a primary step, evaluating the modularity of prefabricated merchandise is important. Thus, this research adopted Hvam et al.’s (2017) framework for product modularity evaluation.

2.4. Modularity Framework to Assess Prefabricated Merchandise

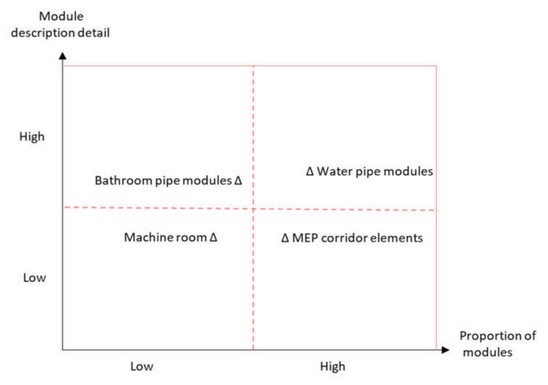

Hvam et al. [14] advised a modularity evaluation framework for classifying merchandise based mostly on their modularity degree (Determine 1). The framework relies on two dimensions: (1) the proportion of the modules ultimately product and (2) the diploma of element for the modules contained ultimately product.

Determine 1. Modularity evaluation matrix [14].

To estimate the proportion of modules, the product modules ought to first be outlined. 2 hundred modules are a part of the product containing self-contained performance [11, 40]. The modules will be designed independently, but when mixed into the ultimate product, they perform collectively as a complete [42]. The module proportion as a share contained ultimately product, similar to in a complete constructing, will be crudely estimated and for renovation tasks, it will be cheap to proportionate the share of modules solely to the renovated a part of the constructing. The evaluation goals to estimate the product’s approximate somewhat than exact placement within the low–excessive axis.

The second dimension of the matrix is the module descriptions. In response to Hvam et al. [14], this specifies “the diploma of element of modules contained within the product—versus the diploma of element of the product itself” (p. 5). Based mostly on Mikkola [43], the diploma of modularity depends upon the elements used, their interfaces, traits, and the chance for alternative. Hvam et al. [14] clarify that the extra concrete the module’s kind, perform, and interfaces are, the upper its product placement. As an illustration, if the general product is loosely outlined, however the used modules have detailed predetermined designs, the product could possibly be positioned on the prime of the matrix [44]. Equally, if the product is totally custom-made for a selected building venture and its necessities, the module description element degree is usually low.

Based mostly on the framework, any product could possibly be situated in one of many 4 corners. The estimation for each dimensions could possibly be accomplished principally subjectively with out utilizing any particular method or equations. Thus, the precise location of the product isn’t the purpose, however the capacity to check completely different merchandise is. The very best modularity degree is materialized when the entire finish product consists of modules with a excessive diploma of element.

2.5. Connecting the Degree of Modularity in Prefabricated Merchandise to Venture Efficiency

This part goals to synthesize the literature on prefabrication in building and product modularity and develop propositions on the impacts of prefabricated and modular merchandise on venture efficiency. The extensively mentioned advantages of modularity embrace simplifying the designs, lead time reductions, and the standardization and prefabrication of subsystems [10]. Exterior of building, modularity can be a significant means for growing competitiveness [10,39]; nevertheless, the diploma of modularity depends upon the elements adopted, their interfaces, and the chance for modular alternative [43]. Based mostly on the earlier literature, we recommend the next:

P1: The extent of modularity of the prefabricated product adopted in a building venture is immediately proportional to the extent of the gained advantages.

Proposition 1 means that prefabrication impacts will be elevated by growing the proportion of modular prefabricated merchandise ultimately product, by growing the diploma of element within the modular prefabricated merchandise, or by each. This enchancment ought to be doable even with out shifting from one prefabricated product kind to a different. When contemplating the proportion of modules in a constructing, one can argue that this proportion is usually extremely depending on the prefabricated product kind. Using modular constructing manufacturing strategies means the proportion of modules is excessive. However, utilizing non-volumetric pre-assembly merchandise implies that a lot of the meeting and becoming and ending work entails no prefabricated modules (e.g. [10]). Subsequently, after we undertake a selected prefabricated product kind within the venture, our particular consideration ought to be positioned on the impacts of the diploma of element on the advantages. Hvam et al.’s [14] framework emphasizes the product’s detailed module description, with tasks benefiting from detailed info for all phases of the venture design and set up course of [45]. Baldwin and Clark [42] additional point out that merchandise don’t profit from modularization rules until such merchandise are composed solely of modules which can be described intimately. Within the building context, we argue that description particulars are sometimes outlined on the venture degree, resulting in prototype issues, not less than if the repetition doesn’t enable for a steep studying curve contained in the venture. Subsequently, we argue that predefined detailed module descriptions ought to profit the venture when utilizing sure prefabricated product sorts. These arguments result in the second proposition:

P2: Prefabricated merchandise with detailed module descriptions are extra useful than these with much less detailed ones.

Gosling et al. [46] highlighted module description-related issues in prefabricated buildings, similar to incorrect specs, a scarcity of meeting alignments, the on-site coordination of deliveries and trades, and knowledge move points. These principally non-monetary issues could possibly be resolved by offering detailed module descriptions, as an illustration, appropriate module kinds, features, and specs. Subsequently, we argue that implementing prefabricated merchandise with extremely detailed module descriptions ought to ultimately present extra non-monetary advantages, similar to employee satisfaction, advantages from earlier venture completion, and higher security and ergonomics [13].

P3: Larger module description element results in larger non-monetary advantages. We subsequent current our analysis methodology to validate and elaborate on the outlined propositions empirically.

3. Technique

Our analysis’s fundamental goal was to create new data concerning prefabricated merchandise’ specified impacts when modularity is taken under consideration and to create new data on the connections between prefabricated product sorts, the extent of modularity, and their a number of impacts on tasks. This requires an in-depth evaluation of a number of product sorts carried out in actual tasks. In response to Yin [47], a a number of case research is an appropriate method to analyze this sort of drawback. Moreover, a number of sources of proof can be utilized to extend reliability and since our analysis considers the non-monetary advantages of prefabrication, a number of sources of knowledge have been vital for the evaluation. Thus, this analysis was carried out based mostly on a a number of case research evaluation.

3.1. Case Choice

Seawright and Gerring [48] have advised seven case-selection methods: typical, various, excessive, deviant, influential, most related, and most completely different. On this analysis, we employed probably the most completely different process to find out the impacts of various prefabricated merchandise through a cross-case evaluation. By choosing completely different prefabrication instances by way of their modularity dimensions, we might look at the connection between the product traits and the a number of impacts. We selected a case involving volumetric prefabricated merchandise (prefabricated machine room) and three instances involving non-volumetric prefabricated merchandise (toilet pipe module, MEP hall parts and water pipe modules).

4.

Prefabricated machine room: This case is an workplace constructing venture by which a prefabricated machine room was designed, produced, and put in. The machine room included all of the technical tools inside a single metal body with exteriors and a roof. The room included pre-assembled automation and management methods, warmth distribution and restoration methods, refrigeration home equipment, water, and electrical energy provide methods. The information originated from an interview with the venture supervisor, product description experiences, and a web site go to report.

5.

Rest room pipe module: This case carried out the prefabricated toilet pipe module product consisting of water pipes, sewer pipes, and bathrooms. This product is manufactured based mostly on the lavatory measurement, and its weight is about 55 kg. The lavatory pipe module has been carried out in a number of tasks in several elements of the world. For this research, we now have analyzed the impacts of this product in a residential renovation venture in the midst of Finland, which consists of a five-story constructing, 4 staircases, and 52 residences. Every house consists a WC with a 3 m2 space. The case is analyzed based mostly on the fee information, interview with the product developer, product description experiences, and experiences shared by web site managers and engineers.

6.

Mechanical, electrical, and plumbing hall parts: This case adopted prefabricated MEP hall parts put in in an workplace constructing. The MEP contractor had carried out related prefabricated MEP racks with heating, cooling, air flow pipes, and electrical wires in a number of tasks. The information originated from venture experiences, web site go to experiences, and an interview with the venture supervisor.

7.

Water pipe modules: We analyzed prefabricated home water pipe modules put in in a plumbing renovation venture. The venture concerned 6 buildings and 164 residences. The case was investigated based mostly on a web site go to, interviews with the contractor’s and shopper’s representatives, and a focus-group dialogue (FGD) with an installer and web site engineers.

3.2. The Modularity of the Chosen Instances

Hvam et al.’s [14] framework was adopted to guage the modularity of the chosen case merchandise (Determine 2). Placement of the mannequin’s merchandise isn’t based mostly on any explicit method however on subjective and relative placement inside the dimensions.

Determine 2. Approximate modularity of the chosen instances.

Rest room pipe modules: This renovation venture carried out prefabricated toilet pipe module merchandise. Different elements of the constructing have been designed and renovated following conventional strategies. The module producer described the specs, kinds, and features of the lavatory pipe modules and elements intimately. In abstract, the answer was positioned within the prime left quadrant of the matrix.

Machine room: This resolution included a single module designed and put in within the venture. Despite the fact that the module was somewhat massive, it was solely a small share of the entire workplace constructing venture. In response to the venture supervisor, the module was fairly complicated to put in. As a project-specific and distinctive product, the outline element concerning the product was not nice initially. Thus, regardless that the machine room was prefabricated, the product was positioned within the backside left space of the matrix.

Mechanical, electrical, and plumbing hall parts: This case carried out prefabricated MEP hall parts, together with a MEP rack with heating, cooling, air flow, and electrical methods. The answer coated fairly a big a part of the entire workplace constructing venture; nevertheless, the modules have been designed for this particular constructing with out main design and interface standardization. Subsequently, it was positioned on the underside proper quadrant of the matrix.

Water pipe modules: The answer was based mostly on a business pipe module product developed by a Finnish firm. The usual pipe design was utilized and fitted to the constructing. The pipe modules have been put in in stairwells and residences. Based mostly on the positioning measurements, pipes have been pre-cut within the manufacturing facility after which delivered to the positioning. Because the venture’s scope centered on a home water system renovation, a big proportion of the venture was carried out by way of the modules. Throughout the web site go to, the positioning supervisor talked about that the product was simpler to put in as its specs and kinds have been described intimately. In abstract, the product was positioned within the prime proper space of the modularity matrix.

3.3. Knowledge Assortment and Evaluation

After choosing the instances, information have been collected for within- and cross-case analyses [10], with the recognized high quality, supply, value, and suppleness because the aggressive priorities to contemplate whereas evaluating the manufacturing system. Thus, to guage the influence of prefabrication, we used the choosing-by-advantage (CBA) methodology developed by Suhr [49], because it has been discovered to be probably the most acceptable methodology for selecting alternate options [50]; nevertheless, Suhr [49] didn’t present clear tips concerning a financial issue evaluation. Consequently, Chauhan et al. [13] argued that CBA can be more practical if the fee elements could possibly be evaluated based mostly on a price–profit evaluation to account for oblique financial results. Thus, this research combines CBA with a price–profit evaluation of value elements (Determine 3).

Determine 3. The choosing-by-advantage steps, in response to Arroyo et al. [50].

The CBA course of we adopted started by defining the prefabrication resolution and any on-site alternate options, figuring out probably the most possible impacts of the answer or components prone to have an effect on manufacturing, defining evaluation standards to check alternate options, describing every issue’s attributes and the benefits of every attribute, and marking the least most popular attributes. Essentially the most difficult stage was deciding on the significance of benefits (IoAs). Based mostly on public paperwork, interviews, and observations, every benefit’s IoA factors have been agreed upon in an FGD session. The FGD included 17 main Finnish structure, engineering and building (AEC) corporations representing completely different building, design, constructing product, and IT corporations.

We then adopted the European Fee [51] tips to hold out a price–profit evaluation by evaluating the whole prices of standard building with the whole prices of prefabrication. We first evaluated the whole value of standard building and the direct prices of the prefabricated merchandise. We then recognized all the advantages and downsides of the prefabricated merchandise and transformed these impacts into prices. Then, value–profit ratios have been calculated for every case.

3.4. Inside- and Cross-Case Analyses

As an final result, the CBA evaluation enabled us to check the standard and prefabricated options in all 4 instances and conduct a cross-case evaluation of the relative impacts of the 4 analyzed case merchandise.

A cross-case evaluation helps to establish patterns by trying on the information in divergent methods and growing the likelihood of capturing novel findings [47]. Following Yin [47], we first carried out a within-case evaluation by evaluating every resolution with its various in conventional on-site building utilizing a price–profit evaluation and CBA to find out a efficiency measurement. Then, the 4 instances and their performances have been in contrast for various dimensions (product class, degree of modularity, and the financial and non-monetary impacts of the merchandise) to check and elaborate on our propositions.

4. Evaluation and Outcomes

4.1. Inside-Case Evaluation

For our in-depth case evaluation, CBA was used, the place the financial components have been analyzed based mostly on a price–profit evaluation.

4.1.1. Case I: Rest room Pipe Module

1. Selecting-by-advantage.

The CBA outcomes for the lavatory pipe module are introduced in Desk 2. In response to the on-site interviews and discussions, the key recognized non-monetary advantages have been being simpler to put in, having a shorter venture schedule, and the next high quality; nevertheless, the design uncertainty and availability of the installers have been discovered to be the benefits of the traditional methodology.

Desk 2. Selecting-by-Benefit for Rest room Pipe Module (EUR 1000).

| Components | Various 1: Rest room Pipe Module | Imp | Various 2: Typical | Imp |

| Set up | Att: Simpler to put in Adv: 2–3 occasions simpler than standard | 60 | Att: Troublesome to put in Adv: | |

| Venture schedule | Att: Quick to assemble Adv: 5–15% quicker than standard | 58 | Att: Slower when constructed on-site Adv: | |

| High quality | Att: Larger high quality, much less upkeep Adv: 2–3 occasions larger high quality then standard | 60 | Att: Decrease high quality, requires extra upkeep Adv: | |

| Design uncertainty | Att: No entry to the unique supply for design Adv: | – | Att: Put in within the precise location Adv: Decrease uncertainty with design | 40 |

| Availability of installer | Att: Generally tough to search out skilled installers Adv: | – | Att: All of the subcontractors are following the standard mechanism Adv: Simply obtainable installer | 25 |

| Complete IofAs | 178 | 65 |

Key: Att = attributes; Adv = benefit, Imp = significance, IoAs = significance of benefits.

From the attitude of the product producers, the set up means of the lavatory pipe module product is 2–3 occasions shorter than in standard building and the product is mild and straightforward to put in on the lavatory wall. Within the conventional methodology, the installer must spend extra time connecting small elements required for the ultimate product.

On this venture, toilet renovation time was decreased by 5–15% in contrast with the traditional methodology. General, the venture staff estimated that the entire web site schedule was decreased by per week. Moreover, earlier completion of the lavatory helped subcontractors prepare toilet employees to be concerned in different actions, which helped preserve the streamlined workflow. Noise and dirt have been additionally decreased, which made the circumstances higher and simpler for the employees and neighbors.

The standard of the prefabricated toilet module was considerably larger than within the standard renovation methodology. Pipes used to fabricate this product have been breakable in a number of elements that will make it simpler to establish doable issues with the pipe and leakage of the system. The product is sealed with soundproof and odor-proof supplies, which immediately advantages the client. Moreover, the producer assumes that the necessity for upkeep can be considerably decrease than within the conventional methodology.

Regardless of the large benefits of the lavatory pipe modules over conventional building, some limitations have been recognized. For instance, the product producers talked about that getting preliminary details about the set up could possibly be a hurdle, because the design usually incorporates uncertainty. Moreover, the set up requires extra skilled individuals than within the standard methodology.

2.

Value–profit evaluation

The fee–profit evaluation for prefabricated toilet modules versus conventional on-site building is introduced in Desk 3. The direct prices (uncooked supplies, labor, and module installations) have been about 3% decrease than within the standard renovation methodology.

Desk 3. Value–Profit Evaluation for a Prefabricated Rest room Pipe Module (EUR 1000).

| Complete Venture Value (Typical) = 396 | |

| Complete Value of a Typical Renovation of Pipe Module= 374 | |

| Financial components | Value of toilet pipe module in contrast with standard building |

| Direct value (materials, labor, transportation, and set up) | −10 |

| Oblique prices | – |

| Venture schedule | −9 |

| Further work | −18 |

| Complete value | 337 |

| Venture-level profit–value ratio = in complete venture value = 396/359=1.10 > 1 | |

The venture acquired advantages from a number of oblique value components. As an illustration, every staircase was accomplished 1.5 weeks earlier, and a complete of 15% of time was saved in contrast with the traditional methodology. This resulted in 2% financial savings. Moreover, based mostly on the fee information, a number of extra works have been decreased by implementing this product, such because the transportation of smaller elements, fixing the set up, and sustaining a clean workflow. This resulted in about 5% financial savings.

Based mostly on Hvam et al.’s [14] modularity evaluation framework, this case venture belongs to the highest left quadrant because the module of this product was described intimately. The FGD was organized to guage the IofA factors for non-monetary components. The FGD individuals talked about that the detailed product description of the modules was a significant component for them whereas selecting modular bogs over the standard ones and the distinction in significance of the benefit factors between the modular and traditional strategies of the lavatory was 113.

4.1.2. Case II: Machine Room

1. Selecting-by-advantage

Based mostly on the non-monetary benefits and downsides, CBA was utilized, as introduced in Desk 4. The recognized non-monetary components for the machine room included the area, venture schedule, buyer worth, set up, upkeep working circumstances, and design flexibility.

Desk 4. Selecting-by-Benefit for the Machine Room.

| Components | Various 1: Machine Room | Imp | Various 2: Typical | Imp |

| House | Att: Requires much less area, that means much less upkeep and heating Adv: 18% area saved in contrast with standard | 70 | Att: Requires extra space Adv: | |

| Venture schedule | Att: Sooner to assemble, much less uncertainty Adv: 1 week quicker than standard | 40 | Att: Slower to assemble Adv: | |

| Buyer worth | Att: Upkeep service included Adv: Much less downtime for buyer | 60 | Att: Extra downtime for buyer Adv: | |

| Set up of latest machines | Att: Could be complicated to put in Adv: | – | Att: Simpler to put in Adv: Simpler to put in | 40 |

| Upkeep work circumstances | Att: Restricted area blocks employee mobility Adv: | – | Att: No disturbance to employee mobility Adv: | 30 |

| Design flexibility | Att: Design ought to be fastened earlier Adv: | – | Att: Simpler to make adjustments in response to area customers Adv: Simpler to design | 55 |

| Complete IofAs | 170 | 125 |

Key: Att = attributes; Adv = benefit, Imp = significance, IoAs = significance of benefits.

In response to the venture supervisor, about 18% of the room area was saved in comparison with standard building, requiring much less upkeep and heating. These impacts have been analyzed as non-monetary impacts, as correct value results have been arduous to estimate. The venture was accomplished one week quicker than standard implementations, benefiting everybody (contractor, proprietor, buyer). Moreover, a single provider designed the machine room, subsequently, lifecycle assist and resolving later points have been improved.

Nevertheless, a key disadvantage was its difficult set up. As soon as put in, it restricted workforce mobility throughout the subsequent venture part. Designing the prefabricated machine room was additionally extra complicated than in standard building.

Based mostly on the FGD, area was thought of an important benefit issue (70 factors), whereas design flexibility was the least essential, with 55 factors given to its various (i.e., standard).

2.

Value–profit evaluation

The machine room value–profit evaluation is introduced in Desk 5. The direct value was 19% larger than for on-site building. The direct prices included MEP-related and set up prices. The rise was primarily as a result of extra value required on the set up location, the place the ground preparation prices have been larger.

Desk 5. Value–Profit Evaluation for a Prefabricated Machine Room (EUR 1000).

| Complete Venture Value = 4900 | |

| Complete Value of Typical Development = 124 | |

| Financial Components | Value of the machine room |

| Direct value (materials, labor and set up) | +24 |

| Oblique prices | – |

| House (−18%) | −35 |

| Schedule (−1 week) | −6 |

| Co-ordination | −1 |

| Design work | +2 |

| Complete value (direct + oblique) | 108 |

| Venture-level profit–value ratio = 4900/4884 = 1.00 > 1 | |

Main financial savings got here by way of oblique prices. In response to the venture supervisor, about 18% of the everyday machine room area was saved as a result of extra compact prefabricated model, equating to twenty-eight% value financial savings. The set up course of was accomplished about one week quicker, which resulted in a 4.8% saving by way of common situation prices and venture administration prices and about 0.8% coordination value financial savings; nevertheless, some oblique prices have been larger, similar to the extra design value, at about 1.6% greater than for standard design.

This case product is estimated to be within the backside left quadrant of Hvam’s modularity evaluation framework. In comparison with the opposite case, this product was much less modular and had much less description of the product module.

4.1.3. Case III: Water Pipe Modules

1. Selecting-by-advantage

Desk 6 reveals the CBA evaluation for the pipe modules. Implementation of the water pipe modules allowed residents to remain in situ throughout the renovation, which was an enormous benefit.

Desk 6. Selecting-by-Benefit for Water Pipe Modules.

| Components | Various 1: Pipe Modules | Imp | Various 2: Typical | Imp |

| Buyer worth | Att: No have to evacuate Adv: Extra customer-friendly in contrast with standard | 85 | Att: Requires evacuation Adv: | – |

| Venture schedule | Att: Sooner to assemble Adv: 2 weeks per ground quicker than standard | 75 | Att: Slower to assemble Adv: | – |

| High quality | Att: Normal supplies are related Adv: Simpler to detect leakages and join supplies | 70 | Att: No normal supplies are related Adv: | – |

| Documentation | Att: Properly documented Adv: Higher pipe documentation | 65 | Att: Poorly documented Adv: | – |

| Pipe scratching | Att: Larger chance of being scratched Adv: | – | Att: Decrease chance of scratching Adv: | 65 |

| Design | Att: Not appropriate for all buildings Adv: | – | Att: Appropriate for all buildings Adv: Extra appropriate than prefabrication | 55 |

| Complete IofAs | 295 | 120 |

Key: Att = attributes; Adv = benefit, Imp = significance, IoAs = significance of benefits.

The renovation of every staircase was accomplished two weeks sooner than with standard strategies, immediately benefitting the client. Moreover, the water pipe modules have been manufactured in a manufacturing facility, with staged high quality inspections that additionally concerned the insulation, pipe bracket, and high-quality floor inspections. Moreover, the installers talked about that the pipe module documentation was higher than for standard installations.

Nevertheless, prefabricated product floor scratching was reported as a standard drawback throughout set up, which isn’t a problem for standard installations. As well as, the pipe modules have been put in as a visual aspect within the stairways and lobbies, which might not fulfil the aesthetic necessities in all buildings. Moreover, the manufactured modules have very strict tolerances, which could require extra on-site becoming work when mixed with the looser tolerances of the renovated constructing.

General, the FGD considered buyer worth as an important issue (85 factors), whereas pipe scratching was the least essential issue, with 65 factors awarded to standard building.

2.

Value–profit evaluation

The fee–profit evaluation of the water pipe modules is introduced in Desk 7. In response to the positioning supervisor, the direct value was the identical as for standard building. Main financial savings got here by way of oblique prices. The implementation allowed residents to remain of their residences throughout the whole renovation interval; roughly EUR 350,000 of the extra funds would have been wanted to evacuate the residences for standard renovation. Moreover, based mostly on the positioning supervisor’s assumption, every staircase was accomplished two weeks quicker than for standard building.

Desk 7. Value–Profit Ratio for Water Pipe Modules (EUR 1000).

| Complete Venture Value = 2924 | |

| Complete value of standard building = 2624 | |

| Financial Components | Value of pipe modules |

| Direct value (materials, labor and set up) | Identical as in standard building |

| Oblique prices | |

| Evacuation value | −350 |

| Schedule (common situation value + administration value) | −49 |

| Venture schedule (capita value and revenue margin and others) | −147 |

| Complete value (direct + oblique) | 2078 |

| Venture degree profit–value ratio = 1.26>1 | |

This case belongs to the highest proper quadrant of the modularity evaluation framework. The place the case incorporates a excessive variety of modules, and the modules are described intimately. This case product was probably the most engaging product for building stakeholders who participated within the FGD session, the place the IofA distinction was 175, which is the best in contrast with different instances.

4.1.4. Case IV: Mechanical, Electrical, and Plumbing Hall Parts

1. Selecting-by-advantage

The CBA for the MEP hall parts is proven in Desk 8. In response to the venture supervisor, the venture was accomplished 4 weeks sooner than for standard building. He additional assumed that the standard of those parts was higher than for standard merchandise (higher warmth and noise insulation, simpler to put in). The installers confirmed the benefit of set up enabled bodily actions throughout the set up process.

Desk 8. Selecting-by-Benefit for Mechanical, Electrical, and Plumbing Hall Parts.

| Components | Various 1: MEP Hall Parts | Imp | Various 2: Typical | Imp |

| Schedule | Att: Quick to assemble Adv: 4 weeks quicker than standard | 60 | Att: Gradual to assemble Adv: | |

| High quality | Att: Higher soundproofing, higher insulation meeting high quality Adv: Much less sound is transmitted, higher insulation | 55 | Att:Non-standardized setting, disruptions in workflow Adv: | |

| Ergonomics | Att: Permits for motion and stretches Adv: Extra snug to put in | 40 | Att: Poor meeting ergonomics Adv: | |

| Materials danger | Att: Parts required massive holes in partitions Adv: Transportation holes may ease stealing from web site | Att: Simpler to maintain web site locked Adv: | 25 | |

| Design change | Att: Troublesome to vary the design Adv: | Att: Simple to switch areas for rental customers Adv: Simpler to vary the design | 55 | |

| Subcontractor motivation | Att: Decrease motivation of subcontractor Adv: | Att: Typical methodology has beenin apply for a very long time Adv: Larger subcontractor motivation | 30 | |

| Complete IofAs | 155 | 110 |

Key: Att = attributes; Adv = benefit, Imp = significance, IoAs = significance of benefits.

Nevertheless, one problem involved later design adjustments being tough; thus, in following the CBA tips, factors got to the on-site product various. Different FG web site managers talked about hall parts requiring massive wall openings, which elevated the on-site theft danger. As well as, some subcontractors weren’t acquainted with the prefabricated hall parts; it was tough to inspire them to put in these parts because it lowered the subcontractors’ and employees’ piecework pay.

In abstract, the FGD session discovered that the schedule was an important non-monetary issue (60 factors). In distinction, a design change was thought of the least essential issue, with 55 factors assigned to the traditional route.

2.

Value–profit evaluation

The fee–profit evaluation for MEP hall parts is introduced in Desk 9. On this venture, the direct value was discovered to be 11% decrease than for standard building. The fabric prices for the prefabricated merchandise have been larger, however the labor value was decreased considerably resulting from manufacturing facility set up.

Desk 9. The Value–Profit Evaluation of Mechanical, Electrical, and Plumbing Hall Parts (EUR 1000).

| Complete Venture Value = 4200 | |

| Complete Value of Typical Development is 110 | |

| Financial Components | Value of Prefabricated MEP Hall Parts |

| Direct value (materials, labor and set up) | −12 |

| Oblique prices | – |

| Design | +8 |

| Venture schedule (4 weeks) | −23 |

| Conferences | −1 |

| Materials pickup | −1 |

| Complete value | 81 |

| Venture-level profit–value ratio=4200/4171 = 1.01 > 1 | |

Oblique value advantages arose from the implementation. For instance, MEP hall parts have been put in in 28 days on-site, which was 4 weeks shorter than standard building, saving round 20% usually prices in comparison with standard installations.

Throughout the web site go to, the venture supervisor talked about that, resulting from prefabrication, 2–3 days have been saved in subcontractor coordination conferences, leading to a couple of 1% saving in comparison with standard building. As well as, about 1% of the fee was eradicated in materials pickups by using hall aspect prefabricated merchandise.

Whatever the oblique value advantages, prefabrication required extra design prices, with a couple of 7.3% value enhance. A extremely expert designer was required to make detailed fabrication-level designs. As well as, extra coordination was wanted between the designer and contractor.

This case belongs to the underside proper quadrants of the modularity evaluation framework, the place the tip product is estimated to be extremely modular however with much less description of the modules. Despite the fact that the modules have been much less described, the MEP prefabrication was prioritized over its conventional counterparts; nevertheless, in contrast with different case merchandise, this one was much less prioritized with an IofA 45.

4.2. Cross-Case Evaluation and Validation of the Propositions

After the in-depth within-case analyses, a cross-case evaluation was carried out to establish widespread patterns within the instances. We centered on the connections between the extent of modularity and the impacts of the prefabricated merchandise. We first in contrast the instances concerning their financial and non-monetary components (Desk 10 and Determine 4).

Determine 4. Value benefit evaluation.

Desk 10. Cross-Case Evaluation of Chosen Instances.

| Case Product | Product Class | Place in Modularity Evaluation Matrix | Impacts on Financial Components (Venture Degree (B/C)) | Impression on Non-Financial Components (IoA Variations) |

| Rest room pipe module | Volumetric | High left | 1.10 | 113 |

| Machine room | Volumetric | Backside left | 1.00 | 45 |

| MEP hall parts | Non-volumetric | Backside proper | 1.01 | 45 |

| Water pipe modules | Non-volumetric | High proper | 1.26 | 175 |

Based mostly on the evaluation, all instances’ cost-benefit ratios have been above one, which implies they have been all economically useful for implementation. The benefit level distinction between the prefabrication and traditional methodology was additionally constructive in all instances; thus, prefabrication is extra useful from the non-monetary “worth” perspective in contrast with the standard methodology.

When contemplating the project-level value–profit facet and benefit factors, the machine room was the least useful resolution among the many instances. It was additionally characterised by the bottom relative proportion of modules and low module description element. The hall aspect had related non-monetary benefits however barely higher value–advantages. The water pipe modules dominated the machine room in each dimensions. Because the water pipe modules had the best degree of modularity and the machine room the bottom, the findings present indicative assist for proposition 1, stating that the extent of modularity is immediately proportional to the extent of the gained advantages.

The second and third propositions have been associated to the connections between the module description element and prefabrication impacts. Because the water pipe modules had the best venture advantages, the findings additionally assist proposition 2 about extra advantages arising from detailed modular product descriptions. Moreover, the lavatory pipe module’s and the water pipe module’s extremely detailed module descriptions appear to be related to their higher non-monetary impacts. Thus, this discovering strongly helps proposition 3 concerning the upper non-monetary advantages of prefabricated merchandise with detailed module descriptions.

5. Dialogue

Implementing prefabricated merchandise impacts a number of direct and oblique components [7] that have an effect on productiveness within the building trade [52]; nevertheless, the consequences of prefabricated product sorts and modularity on building tasks haven’t but been mentioned within the literature.

Based mostly on the findings, a number of contributions will be made to the prevailing literature on prefabrication and modularity in building. First, we argue that the extent of modularity of the prefabricated product adopted in a building venture is, on common, proportional to the extent of the gained advantages. Many earlier works focus on the advantages of modularity (e.g., [10,12]), and modularity is additional mentioned as one of many main means of accelerating agency competitiveness [39]. Our evaluation signifies that building tasks with the next proportion of modules have the next project-level value–profit ratio than tasks with a decrease share of modules. This was particularly evident when evaluating our water pipe module case with the opposite instances. Extra particularly, the discovering signifies {that a} excessive proportion of modules in a venture is particularly really useful if the key goal of prefabrication is to achieve exceptional value advantages. Earlier analysis has indicated that the necessity for full modular product structure will increase if low prices are prioritized [1]. This analysis extends that data by stating {that a} full modular product structure contributes to larger advantages ensuing principally from benefits in oblique value components, similar to schedule and high quality points, whereas the impacts on direct prices are extra combined.

Second, the evaluation reveals that detailed descriptions of prefabricated modules are related to their non-monetary advantages, which, within the evaluation, have been outlined utilizing the CBA method. Baldwin and Clark [42] defined how merchandise can be extra useful if the product modules have been described intimately. In our analyses, instances with extremely predetermined module descriptions (i.e., water pipe modules and loo pipe modules) had extra non-monetary advantages, similar to time-related, ergonomics, and security, than these with much less detailed descriptions (MEP hall parts and a machine room).

The remark concerning the non-monetary impacts will be prolonged to the dialogue on the productization of the modules. Each the lavatory and water pipe modules merchandise represented options owned and developed by an organization that aimed to make use of the identical detailed resolution in a number of tasks. Conversely, the machine room and MEP hall parts have been designed immediately to satisfy the precise venture’s wants. Subsequently, it may be argued that product possession and utilization in a number of tasks assist the notion of taking non-monetary impacts under consideration. Moreover, this means that product possession and design reuse can assist studying and steady enchancment. In different phrases, project-specific options are likely to give attention to value advantages, and so they could encounter potential challenges with different impacts, similar to these associated to decrease work satisfaction or destructive on-site surprises. In conclusion, choosing prefabricated product sorts for a venture ought to be made fastidiously based mostly on the venture’s priorities.

This analysis adopted the CBA method to guage a number of impacts of prefabricated merchandise in building. The evaluation revealed that the CBA method is an appropriate methodology to check prefabricated merchandise with standard building, particularly when oblique prices on the venture degree are additionally thought of in the fee a part of the evaluation. The CBA method embedded in the fee–profit evaluation is particularly fruitful when evaluating complicated merchandise with multifaceted impacts on many alternative venture stakeholders and it will be more practical to guage the manufacturing methods based mostly on the aggressive precedence components of value, high quality and suppleness [10].

6. Conclusions

This analysis analyzed the impacts of modular and prefabricated merchandise based mostly on a number of case analyses. The instances included a volumetric product (prefabricated machine room) and three non-volumetric merchandise (toilet pipe module, MEP hall parts and water pipe modules). Hvam et al. [14] proposed a modularity evaluation framework based mostly on the proportion of modules and module description element. We used this framework to develop three propositions for prefabrication impacts and examined the propositions through the empirical evaluation of 4 instances.

The cross-case evaluation revealed that prefabricated merchandise that kind a excessive proportion of the venture are extra cost-beneficial than merchandise that kind solely a low proportion of the venture. The implication is that practitioners who purpose to maximise venture cost-efficiency ought to take into account using prefabricated options for a significant a part of the entire venture. In renovation tasks, these options are usually non-volumetric parts, however in new buildings, they might belong to any prefabricated product class from non-volumetric parts to completely modular buildings.

The research additionally revealed that prefabricated merchandise usually have many non-monetary advantages. These extra hidden or mushy advantages, similar to employee satisfaction, security, and ergonomics, could also be simpler to materialize if the used product isn’t solely designed for the venture at hand however has an extended growth and enchancment historical past in a number of previous tasks. Thus, we suggest that practitioners favor productized normal options with current detailed designs in the event that they wish to sort out these non-monetary impacts of their tasks. However, if project-specific options are used, the venture staff ought to pay attention to the potential pitfalls and spend money on competency and sources to keep away from points within the design and execution phases.

This research investigated 4 case options, and subsequently the generalizability of the findings is somewhat restricted. Additional analysis is required to research extra various instances of carried out prefabricated merchandise with high-level modularity and evaluate the advantages with the low-level use of modular merchandise. Furthermore, the impacts of the prefabricated merchandise ought to be evaluated in several venture phases and from completely different stakeholder views. An evaluation of deliberate impacts and realized impacts would additionally reveal probably the most appropriate measurement strategies in every venture stage.

Creator Contributions

Conceptualization, Okay.C. and A.P.; methodology, Okay.C. and A.P.; information curation, R.L.; A.P. and Okay.C.; writing—unique draft preparation, Okay.C.; writing—evaluate and enhancing, A.P.; R.L. and O.S.; supervision, A.P.; venture administration, A.P. and O.S. All authors have learn and agreed to the printed model of the manuscript.

Funding

This analysis was financially supported by the Constructing 2030 Esivalmistuksen pilotointi venture 4106599.

Knowledgeable Consent Assertion

Knowledgeable consent was obtained from all respondents interviewed within the research.

Conflicts of Curiosity

The authors declare no battle of curiosity.

References

1. Peltokorpi, A.; Olivieri, H.; Granja, A.D.; Seppänen, O. Categorizing modularization methods to realize numerous goals of constructing investments. Constr. Manag. Econ. 2018, 36, 32–48.

2. Thamboo, J.; Zahra, T.; Navaratnam, S.; Asad, M.; Poologanathan, Okay. Prospects of growing prefabricated masonry walling methods in Australia. Buildings 2021, 11, 294.

3. Lu, W.; Chen, Okay.; Xue, F.; Pan, W. Looking for an optimum degree of prefabrication in building: An analytical framework. J. Clear. Prod. 2018, 201, 236–245.

4. Bernstein, H.; Gudgel, J.; Carr, D. Prefabrication and Modularization: Growing Productiveness within the Development Trade; Modular Constructing Institute: Charlottesville, VA, USA, 2011.

5. Fard, M.; Terouhid, S.A.; Kibert, J.C.; Hakim, H. Security issues associated to modular/prefabricated constructing building. Int. J. Inj. Management. Saf. Promot. 2015, 24, 10–23.

6. Johnsson, H.; Meiling, J. Defects in off-site building: Timber module prefabrication. Constr. Manag. Econ. 2009, 27, 667–681.

7. Sandanayke, M.; Luo, W.; Zhang, G. Direct and oblique influence evaluation in off-site building: A case research in China. Maintain. Cities Soc. 2019, 48, e101520.

8. Gibb, A.G.F.; Isack, F. Re-engineering by way of pre-assembly: Shopper expectations and drivers. Constructing Analysis and Info 2003, 31, 146–160.

9. Gosling, J.; Schoenwitz, M.; Pero, M.; Towill, D. Defining and categorizing modules in constructing tasks: A world perspective. J. Constr. Eng. Manag. 2016, 142, e04016062.

10. Jonsson, H.; Rudberg, M. Classification of manufacturing methods for industrialised constructing: A manufacturing technique perspective. Constr. Manag. Econ. 2014, 32, 53–69.

11. Ulrich, Okay. The function of product structure within the manufacturing agency. Res. Coverage 1995, 24, 419–440.

12. Gershenson, J.Okay.; Prasad, G.J.; Zhang, Y. Product modularity: Definitions and advantages. J. Eng. Des. 2003, 14, 295–313.

13. Chauhan, Okay.; Peltokorpi, A.; Lavikka, R.; Seppänen, O. Deciding between prefabrication and on-site building: A choosing-by-advantage method. In Proceedings of the Worldwide Group for Lean Development, Dublin, Eire, 1–7 July 2019.

14. Hvam, L.; Herbert-Hansen, Z.N.L.; Haug, A.; Kudsk, A.; Mortensen, N.H. A framework for figuring out product modularity ranges. Adv. Mech. Eng. 2017, 9, 1687814017719420.

15. Hong, J.; Shen, J.Q.; Li, Z.; Zhang, B.; Zhang, W. Obstacles to selling prefabricated building in China: A value–profit evaluation. J. Clear. Prod. 2018, 172, 649–660.

16. Khanazode, A.; Fisher, M.; Reed, D. Advantages and Classes Discovered of Implementing Constructing Digital Design and Development (VDC) Applied sciences for Coordination of Mechanical, Electrical and Plumbing (MEP) Programs on Giant Healthcare Tasks. J. Inf. Technol. Constr. 2008, 13, 324–342. Accessible on-line: https://www.itcon.org/paper/2008/22 (accessed on 20 December 2021).

17. Tam, V.W.Y.; Fung, I.W.H.; Sing, M.C.P.; Ogunlana, S.O. Greatest apply of prefabrication implementation within the Hong Kong private and non-private sectors. J. Clear. Prod. 2015, 109, 216–231.

18. Boyd, N.; Khalfan, M.M.; Masqood, T. Off-site building of house buildings. J. Archit. Eng. 2013, 19, 51–57.

19. Zhai, X.; Reed, R.; Mills, A. Components impeding the off-site manufacturing of housing building in China: An investigation of present apply. Constr. Manag. Econ. 2014, 32, 40–52.

20. Hwang, B.G.; Shan, M.; Looi, Okay.Y. Key constraints and mitigation methods for prefabricated prefinished volumetric building. J. Clear. Prod. 2018, 183, 183–193.

21. Pan, W.; Ibb, A.F.G.; Dainty, A.R. Main UK housebuilders’ utilization of off-site building strategies. Construct. Res. Inf. 2008, 36, 56–67.

22. Molavi, J.; Barral, D.L. A building procurement methodology to realize sustainability in modular building. Procedia Eng. 2016, 145, 1362–1369.

23. Polat, G. Components affecting the usage of precast concrete methods in america. J. Constr. Eng. Manag. 2008, 134, 169–178.

24. Goodier, C.; Gibb, A. Future alternatives for offsite within the UK. Constr. Manag. Econ. 2007, 25, 585–595.

25. Zhang, X.; Skitmore, M.; Peng, Y. Exploring the challenges to industrialised residential constructing in China. Habitat Int. 2014, 41, 176–184.

26. Chan, D.W.; Kumaraswamy, M. An analysis of building time efficiency within the constructing trade. Construct. Environ. 1996, 31, 569–578.

27. Lu, W.; Yuan, H. Investigating waste discount potential within the upstream processes of offshore prefabrication building. Maintain. Power Rev. 2013, 28, 804–811.

28. Li, Z.; Shen, G.Q.; Alshawi, M. Measuring the influence of prefabrication on building waste discount: An empirical research in China. Resour. Conserv. Recycl. 2014, 91, 27–39.

29. Hong, J.; Shen, G.Q.; Mao, C.; Li, Z.; Li, Okay. Life-cycle vitality evaluation of prefabricated constructing elements: An enter–output-based hybrid mannequin. J. Clear. Prod. 2016, 112, 2198–2207.

30. Fortunato, B.R.; Hallowell, M.R.; Behm, M.; Dewlaney, Okay. Identification of security Dangers for high-performance sustainable building tasks. J. Constr. Eng. Manag. 2012, 138, 499–508.

31. MGH Development. Security Administration within the Development Trade: Figuring out Dangers and Lowering Accidents to Enhance Web site Productiveness and Tasks; Development Trade Report; MGH Development: Thorpe Bay, UK, 2013.

32. Jaillon, L.; Poon, C. Sustainable building facets of utilizing prefabrication in dense city setting: Hong Kong case research. Constr. Manag. Econ. 2008, 26, 953–966.

33. Jaillon, L.; Poon, C.; Chiang, Y. Quantifying the waste discount potential of utilizing prefabrication in constructing building in Hongkong. Waste Manag. 2009, 29, 309–320.

34. Lopez, D.; Froese, T. Evaluation of prices and advantages of panelized and modular prefabricated houses. Procedia Eng. 2016, 145, 1291–1297.

35. Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, Okay.L.O.; Qian, S. Comparative financial, environmental and productiveness evaluation of a concrete toilet unit fabricated by way of 3D printing and a precast method. J. Clear. Prod. 2020, 261, e121245.

36. Deng, P.; Pei, S.; van de Lindt, J.W.; Amini, M.O.; Liu, H. Lateral conduct of panelised CLT partitions: A pushover evaluation based mostly on minimal resistance assumption. Eng. Struct. 2019, 191, 469–478.

37. Hassan, M.; Usman, M.; Hanif, A.; Farooq, S.H. Bettering structural efficiency of timber wall panels by cheap FRP retrofitting strategies. J. Construct. Eng. 2020, 27, e101004.

38. Morelli, M.; Brandt, E. A Efficiency Evaluation of Prefabricated Loos Put in within the Nineteen Nineties. Latest Developments in Constructing Analysis Strategies, Constructing Pathology and Rehabilitation, fifth ed.; Delgado, J., Ed.; Springer: Singapore, 2016.

39. Miller, T.D.; Elgärd, P. Defining modules, modularity and modularization: Evolution of the idea in a historic perspective. In Proceedings of the thirteenth IPS Analysis Seminar, Fuglsoe, Denmark, 20–21 April 1998.

40. Voordijk, H.; Meijboom, B.; Han, J. Modularity in provide chains: A a number of case research within the building trade. Int. J. Oper. Prod. Manag. 2006, 26, 600–618.

41. Wuni, I.Y.; Shen, G. Essential success components for modular built-in building tasks: A evaluate. Construct. Res. Inf. 2020, 48, 763–784.

42. Baldwin, C.Y.; Clark, Okay.B.; Managing in an Age of Modularity. Managing in an Age of Modularity. Harvard Bus. Rev. 1997, 75, 84–93. Accessible on-line: https://hbr.org/1997/09/managing-in-an-age-of-modularity (accessed on 15 January 2022).

43. Mikkola, J.H. Capturing the diploma of modularity embedded in product architectures. J. Prod. Innov. Manag. 2006, 23, 128–146.

44. Praslov, J.; Morstensen, N. Interface definitions in literature: A actuality test. Concurr. Eng. 2015, 23, 183–198.

45. Seol, H.; Kim, C.; Lee, C.; Park, Y. Design course of modularization: Idea and algorithm. Concurr. Eng. 2007, 15, 175–186.

46. Gosling, J.; Towill, D.R.; Naim, M.M.; Dainty, A.R.J. Ideas for the design and operation of engineer-to-order provide chains within the building sector. Prod. Plan. Management. 2015, 26, 203–218.

47. Yin, R.Okay. Case Research Analysis and Purposes, sixth ed.; Sage: Newcastle upon Tyne, UK, 2018.

48. Seawright, J.; Gerring, J. Case choice strategies in case research analysis: A menu of qualitative and quantitative optinos. Political Res. Q. 2008, 61, 294–308.

49. Suhr, J. The Selecting-by-Benefits Decisionmaking System; Greenwood Publishing Group: Westport, CT, USA, 1999.

50. Arroyo, P.; Tommelein, I.D.; Ballard, G. Evaluating AHP and CBA as choice strategies to resolve the selecting drawback in detailed design. J. Constr. Eng. Manag. 2015, 141, 04014063.

51. European Fee. Information to Value–Profit Evaluation of Funding Tasks. December 2014. Accessible on-line: https://ec.europa.eu/regional_policy/sources/docgener/research/pdf/cba_guide.pdf (accessed on 15 December 2021).

52. Hasan, A.; Baroudi, B.; Elmualim, A.; Rameezdeen, R. Components Affecting Development Productiveness: A 30-Yr Systematic Evaluate. Eng. Assemble. Archit. Manag. 2018, 25, 916–937. Accessible on-line: https://www.emerald.com/perception/content material/doi/10.1108/ECAM-02-2017-0035/full/html (accessed on 15 December 2021).

Educational Editor: Srinath Perera https://doi.org/10.3390/buildings12040459

Obtained: 20 February 2022 / Revised: 20 March 2022 / Accepted: 23 March 2022 / Printed: 7 April 2022